What Is A Tension Load Cell And How Does It Work?

January 27, 2025

Load cells convert mechanical forces into measurable electrical signals, playing a fundamental role in various industrial applications. Among them, tension load cells measure tensile forces, which are important for assessing the strength and integrity of materials and structures under stress. These sensors foster accurate force measurement, making them indispensable in construction, manufacturing, and material testing.

What is a Tension Load Cell?

A tension load cell is a specialized force sensor designed to measure tensile forces—forces that pull or stretch an object. These load cells are essential in industries such as manufacturing, construction, and material testing, where precise force measurement is critical for quality control and structural integrity. A tension load cell converts mechanical tension into an electrical signal through strain gauges, which detects deformation when force is applied. As the load cell stretches under tension, the strain gauges alter their resistance, generating an electrical output proportional to the applied force. This precise measurement capability makes tension load cells important in various applications, including material testing and structural monitoring.

How Does a Tension Load Cell Work?

Tension load cells operate using strain gauge technology, which converts mechanical force into an electrical signal. The process involves the following steps:

- ✔ Application of Force: When a tensile force is applied, the load cell's structure experiences slight elongation.

- ✔ Strain Gauge Response: The strain gauges attached to the load cell stretch or compress, causing a small but measurable change in their electrical resistance.

- ✔ Signal Conversion: A Wheatstone bridge circuit processes this resistance change, converting it into a proportional electrical voltage.

- ✔ Output Signal: The electrical signal is then transmitted to a readout device or data acquisition system, displaying the precise force measurement.

A practical analogy is stretching a rubber band—when pulled, it elongates, and the tension increases. Similarly, a tension load cell translates this mechanical strain into an accurate electrical output.

Types of Tension Load Cells

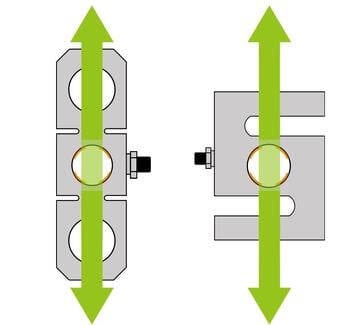

1. S-Type Load Cells

Description: Named after their distinct "S" shape, these load cells are versatile and can measure both tension and compression forces. They provide high accuracy and are commonly made from alloy steel or stainless steel.

Applications: Used in material testing machines, industrial weighing systems, and force measurement applications in automation and robotics.

2. Inline Tension Load Cells

Description: Cylindrical or rod-shaped load cells designed to be installed directly in-line with a load-bearing component, such as a cable, rod, or chain. They provide high accuracy in tensile force measurement.

Applications: Used in crane scales, tensile testing machines, and wire tension monitoring systems.

3. Tension Link Load Cells

Description: These load cells are suspended between two attachment points (such as shackles or eye bolts) and measure force applied along their axis. They are typically rugged and designed for heavy-duty applications.

Applications: Used in overhead lifting, hoist systems, marine applications, and aerospace testing.

4. Pancake (Low Profile) Load Cells

Description: Designed as flat, disc-shaped sensors, these load cells provide high accuracy and are used when space is limited. They often measure both tension and compression forces.

Applications: Used in structural load testing, robotics, and precision weighing systems.

5. Canister Load Cells

Description: These cylindrical load cells are built for high-capacity tension force measurement. They often include hermetic sealing for use in harsh environments.

Applications: Heavy industrial lifting, cable tension monitoring in bridges, and construction applications.

6. Load Pin Load Cells

Description: A pin-shaped sensor that replaces a standard mechanical pin in a load-bearing system, measuring shear force instead of direct tension.

Applications: Used in pulley systems, crane hooks, and anchor points in offshore and marine industries.

Applications of Tension Load Cells

Tension load cells are widely used in:

✔ Crane and Hoist Systems: Monitoring lifting forces to ensure safety and prevent overloads.

✔ Material Testing: Measuring tensile strength of materials like cables, ropes, and metals.

✔ Industrial Weighing: Used in hanging scales and force measurement applications.

✔ Structural Monitoring: Ensuring stability in bridges, towers, and tensioned cables.

With their precision and reliability, tension load cells are indispensable in industries requiring accurate tensile force measurement

Key to Precision in Industrial Applications

A tension load cell measures tensile forces through precise strain gauge technology, playing an important role in various industrial applications such as crane scales and manufacturing processes. The versatility of tension-compression load cells, capable of measuring tension and compression, underscores their importance in safety.

Explore our selection of tension load cells at Load Cell Central to seek professional advice and find the best solution for your needs!