Types Of Load Cells: Which One Is Right For Your Application?

January 27, 2025

In industries where precision and reliability are critical, load cells have become indispensable. These electro-mechanical sensors efficiently convert mechanical force into electrical signals, providing accurate weight and force measurements for a wide range of applications. In this guide, we explore the core principles of load cells, examine their various types, and highlight their significance across industries to help you select the ideal solution for your needs.

Understanding Load Cells

Introduction to Load Cells

A load cell is an electro-mechanical sensor designed to measure force or weight by converting mechanical energy into an electrical signal. This conversion is based on the principle of deformation.

When a load is applied, the load cell deforms slightly, and this deformation is measured by strain gauges bonded to its surface. The resulting change in the resistance of these gauges is proportional to the applied force.

Importance of Load Cells Across Industries

Load cells are versatile devices that play a crucial role in various industries by converting mechanical force into an electrical signal, enabling accurate weight and force measurements. Their precision and adaptability make them valuable tools across sectors such as:

- Industrial Weighing

- Manufacturing

- Automotive Industry

- Medical Applications

- Agricultural Sector

- Aerospace Engineering

- Oil & Gas Industry

- Geotechnical Engineering

Types of Load Cells

Strain Gauge Load Cells

Strain gauge load cells are widely used for measuring force and weight by converting mechanical strain into an electrical signal. They feature a metal element that deforms under load, causing a change in resistance in the attached strain gauges. This change is directly proportional to the applied load, enabling precise measurements. Strain gauge load cells are known for their high accuracy, often achieving tolerances within 0.03% of full scale.

Hydraulic Load Cells

Hydraulic load cells convert mechanical force into hydraulic pressure. When a load is applied, it compresses a diaphragm, increasing the pressure of the hydraulic fluid inside. This pressure change is measured and calibrated to determine the applied force. Known for their durability and resistance to environmental factors, hydraulic load cells are often accurate to within 0.1% or better.

Pneumatic Load Cells

Pneumatic load cells use compressed air to measure force. When a load is applied, it compresses the air within a chamber, creating a pressure change proportional to the applied force. These load cells are often used in environments where electrical components may pose safety risks, such as food processing or hazardous zones.

Capacitive Load Cells

Capacitive load cells measure changes in capacitance caused by variations in the distance between conductive plates due to applied loads. As the distance between the plates changes, the capacitance varies, allowing for precise weight measurement.

Piezoelectric Transducers

Piezoelectric transducers generate an electrical charge when subjected to mechanical stress. As a load is applied, the piezoelectric material deforms, producing a voltage proportional to the force exerted. These transducers are highly sensitive and ideal for measuring dynamic loads with rapid response times, making them perfect for impact testing and vibration analysis.

Specialized Load Cell Types

Thru-Hole Load Cells

Thru-hole load cells, or donut load cells, measure force through a central opening, making them ideal for applications involving bolts or shafts. Constructed from stainless steel, they can handle capacities ranging from 100 lbs to over 1 million lbs.

In-Line Load Cells

In-line load cells are designed to measure tensile or compressive forces along a single axis. They are commonly used in material testing and dynamic weighing applications, as they are installed directly in the load path for precise force measurement.

Pancake Load Cells

Pancake load cells are flat, disc-shaped sensors that provide high accuracy and stability for measuring compressive loads. Their design ensures even distribution of force across the sensing element, minimizing errors caused by off-axis loads.

Column Load Cells

Column load cells are vertical sensors built to measure heavy loads with high accuracy. They are often used in applications such as truck scales and platform scales, where they can efficiently handle compressive forces.

S-Beam Load Cells

S-beam load cells, shaped like the letter "S," are used for measuring both tension and compression forces. Their design allows for versatility, making them suitable for applications like hanging scales or structural testing. They provide high accuracy and can be mounted in various orientations.

Load Button Load Cells

Load button load cells are small, cylindrical sensors designed for measuring compressive forces in confined spaces. These sensors offer high precision and are frequently used in applications where accurate force measurement is required without significant height constraints.

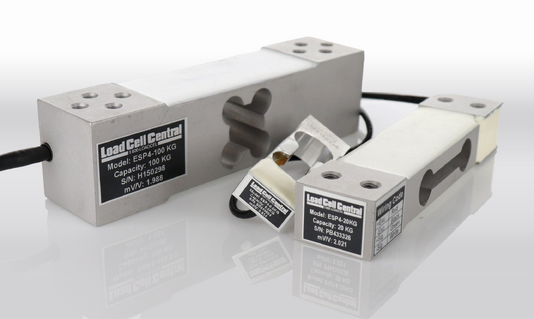

Single-Point Load Cells

Single-point load cells are designed to measure loads applied at a single point. These are ideal for platform and bench scales, as they ensure accurate measurements regardless of the load’s position on the cell, enhancing their versatility in various applications.

Multi-Axis Load Cells

Multi-axis load cells are capable of measuring forces along multiple axes simultaneously. They are commonly used in complex applications, such as robotics and aerospace testing, where they detect both shear and axial loads to provide comprehensive data on the forces acting on an object.

Applications of Different Load Cell Types

Industrial Automation

- Strain Gauge Load Cells: Widely used in automated weighing systems, particularly in processes like filling, batching, and quality control within manufacturing environments.

- Pneumatic and Hydraulic Load Cells: Used in environments requiring explosion-proof solutions, such as chemical processing plants.

Weighing Scales and Balances

- Single-Point Load Cells: Perfect for retail scales and platform scales, offering compact designs and the ability to handle off-center loads effectively.

- Canister/Ring Load Cells: Ideal for heavy-duty applications like truck scales and tank weighing systems, where high capacity and stability are crucial.

Material Testing and Research

- Pancake Load Cells: Suitable for fatigue testing of materials due to their ability to measure both tension and compression accurately.

- Miniature Load Cells: Used in research settings for high-capacity applications in confined spaces, offering precise measurements in experimental setups.

Aerospace and Automotive Industries

- Dynamometer Load Cells: Specialized for measuring torque and power output in engines, essential for testing automotive performance under various conditions.

- Helical Load Cells: Designed to measure off-axis loads in automotive seat weight testing, providing accurate readings even in dynamic conditions.

Medical and Pharmaceutical Applications

- Capacitive Load Cells: Commonly used in laboratory environments where cleanliness is critical. Their design minimizes contamination risks and is ideal for precise small weight measurements.

- Strain Gauge Load Cells: Frequently used in medical devices for patient weighing and accurate dosage measurement, thanks to their high sensitivity and reliability.

Choosing the Right Load Cell for Your Needs

Selecting the Ideal Load Cell

Choosing the right load cell involves understanding the different types, assessing specific requirements, and considering environmental factors. Key considerations include:

- Load Capacity and Range: Ensure the load cell can handle the maximum load expected for your application, with a margin for safety.

- Accuracy and Precision: Select a load cell based on your accuracy needs, considering factors like non-linearity, hysteresis, and repeatability.

- Environmental Conditions: Choose a load cell designed to withstand specific environmental factors such as temperature, humidity, and potential exposure to vibrations or electromagnetic fields.

- Cost and Budget: Balance cost with the required specifications to avoid compromising on performance. Consider the total cost of ownership, including calibration and maintenance over time.

- Compatibility with Data Acquisition Systems: Ensure the load cell integrates seamlessly with your data acquisition system for accurate data collection and analysis.

Tips for Ensuring Optimal Performance

- Regular Calibration: Implement a calibration schedule to maintain accuracy according to industry standards.

- Proper Installation: Follow installation guidelines to prevent misalignment and ensure reliable measurements.

- Routine Maintenance Checks: Perform inspections, especially in harsh environments, to detect wear and tear.

Custom Load Cell Solutions

In cases where standard load cells don't meet your specific application needs, custom solutions can be designed. These can be tailored for unique size, shape, or performance criteria, providing the precision and durability required for specialized applications.