Beam Load Cell Fundamentals: Definition, Principles, And Design Essentials

June 12, 2024

The beam load cell is the most used type of load cell in load cell technology. Beam load cells are known for their versatility and precision. They play a pivotal role in various industries, from manufacturing to aerospace.

Understanding the definition, principles, and design of beam load cells is essential for engineers and practitioners alike. In this exploration, we uncover the details of beam load cells, exploring their principles and design elements that underpin their functionality and widespread application.

Understanding Beam Load Cells

Definition of Beam Load Cells

Beam load cells are specialized transducers that help measure forces applied to them.

They are shaped like a beam, which is where they get their name. The beam portion or the body of the load cell, is composed of metal that is minimally elastic. This means that it always returns to its original shape after bending or deforming.

When force is applied to the load cell it very slightly changes shape. Strain gauges secured to the interior of the load cell change shape with it. An electric current running through those strain gauges experiences a change in resistance. The amount of this change can be used to calculate the weight of the force applied.

Role and Functionality of Beam Load Cells

Beam load cells play a significant role in many areas where knowing the exact weight of something is essential.

- Precision Measurement: Beam load cells serve as essential instruments for accurately measuring the weight or force applied to them. Their design allows for precise readings. This precision makes them invaluable in applications where accuracy is vital, such as in industrial scales and weighing systems.

- Versatility in Applications: Beam load cells find extensive use across various industries and settings. From industrial manufacturing and logistics to aerospace and healthcare, these versatile devices are utilized in diverse applications. This includes material testing, inventory management, and patient monitoring systems.

- Structural Integrity: One of the key features of beam load cells is their solid construction, which ensures structural integrity and reliability even under demanding conditions. This durability makes them suitable for heavy-duty industrial environments where ruggedness is essential for long-term performance.

- Enhanced Efficiency and Productivity: By providing accurate and real-time weight or force measurements, beam load cells contribute to enhanced efficiency and productivity in various processes. Their role in automating tasks, optimizing resource allocation, and monitoring performance leads to improved operational outcomes and cost savings for businesses.

Working Principles of Beam Load Cells

Beam load cells are critical components in various weighing systems, utilizing advanced technology to convert force into measurable electrical output. At the core of their functionality are strain gauge technology and the Wheatstone bridge circuit. These 2 components form the foundation of precise and reliable measurements. Understanding how these elements work together is essential for professionals using or designing systems with beam load cells.

Strain Gauge Technology

The primary technology in beam load cells is the strain gauge, which measures the amount of strain (or deformation) in an object when subjected to a force. It is made of a fine conductor wire or etched foil that has been arranged in a tight, zigzag “grid” and is then attached to an electrically insulating backing. Lead wires (gauge leads) are attached to supply the electrical current.

When the strain gauge experiences strain (a change in shape when force is applied), the electrical current passing through the conductor experiences a change in resistance. This resistance can be determined using the resulting voltage drop (comparing input and output voltage).

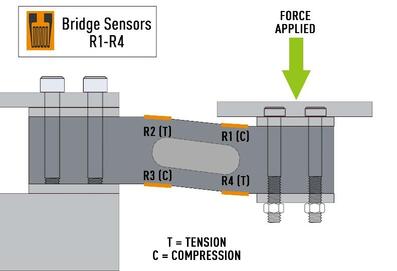

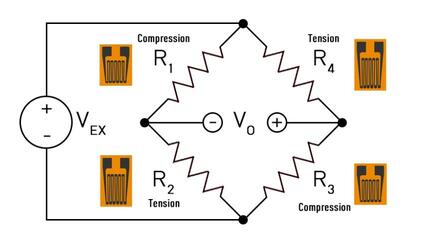

Used in a load cell, four strain gauges are bonded to a bored-out portion of the interior of the body of the load cell. These strain gauges are arranged in a Wheatstone Bridge.

Wheatstone Bridge Circuit

To effectively measure the small changes in the resistance the strain gauge offers, beam load cells employ a Wheatstone bridge circuit. This circuit consists of four resistive arms forming a bridge that can detect minute variations in resistance. In typical load cell applications, all four of these resistors is a strain gauge.

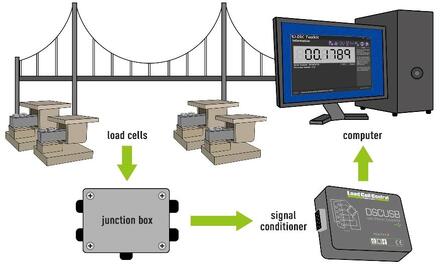

Load Cell Output Signal

The output signal from a beam load cell is typically a tiny voltage change that is too subtle to be used directly by most display or control devices. Therefore, it is amplified by a signal conditioner. This amplified output can then be converted from analog to digital form if required by the system’s readout or control unit.

Essential Design Features of Beam Load Cells

Beam load cells are critical components in weight and force measurement. They are widely used in scales, industrial systems, and other measuring devices due to their accuracy and reliability. Understanding the essential design features of beam load cells helps select the appropriate type for specific applications.

Materials Used in Construction

The choice of material for beam load cells is critical as it directly influences the cell's durability, sensitivity, and overall performance.

Alloy steel is the material most often used in load cell construction. It is ideally suited for use in standard environments where moisture and corrosive materials are not present. Stainless steel is used in applications that require resistance to rust and corrosion, making it suitable for harsh environments.

Aluminum, while lighter and less expensive than stainless steel, is used in applications requiring high sensitivity and lower capacities. For highly aggressive industrial environments, nickel-plated steel or special alloys can be used to provide extra resistance against corrosive forces.

Types of Beam Load Cell Designs

Beam load cells are categorized primarily based on the strain gauge configuration and the beam type. The two prevalent designs are:

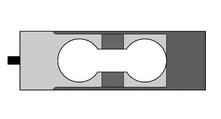

- Single Point Load Cells: These are designed for off-center loading and are commonly used in retail scales, small hopper scales, and other weighing systems where the load may not be perfectly centered. Their design allows them to maintain accuracy across a wide loading area.

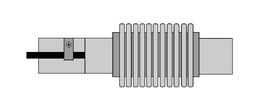

- Bending Beam Load Cells: Bending beam load cells measure forces that bend the body of the load cell in one direction without horizontal or torsional forces. They are typically used in industrial weighing systems, including tank, hopper, and track scales. They are bolted at one end and loaded at the other, offering stability and accuracy.

- Shear Beam Load Cells: Shear beam and double-ended shear beam load cells are physically and functionally like bending beam load cells. However, they have the added ability to measure shear force caused by uneven loading.

Factors Influencing Design Selection

Several factors influence the selection of a beam load cell design:

- Capacity: The maximum weight capacity and the precision requirements of the application are crucial in determining the type of load cell. The capacity of your load cell should exceed the expected maximum load by 25%-30%. Bending beam load cells can be used up to 1,500 lbs. Shear beams are used for higher capacity applications up to 75,000 lbs.

- Environment: Environmental conditions such as temperature, humidity, and potential corrosive elements dictate the material choice and design type. Stainless steel and specially coated materials are preferable for adverse conditions.

- Physical Constraints: The available space and mounting requirements also affect the selection. Bending beam load cells, for instance, are compact and versatile for limited spaces.

- Method and Direction of Load: Bending beam load cells are highly accurate in applications where the load is applied along the load cell’s center axis. Shear beam load cells are designed to maintain accuracy in the event of side or off-center loading resulting in shear strain.

On the other hand, single-point load cells are moment compensated, meaning that they can compensate for unbalanced loading. Single-point load cells are often referred to as platform load cells. When the load cell is mounted under a platform, loads can be applied anywhere on the platform and the readings from the cell remain consistent.

Applications of Beam Load Cells

Beam load cells are essential for various industrial applications due to their reliability, precision, and versatility. Their applications span different sectors, including industrial materials handling systems, automated manufacturing processes, agricultural feeding and supply management, aerospace center of gravity systems, and much more.

Industrial Weighing Systems

In industrial environments, weighing systems are critical for managing materials and products. Beam load cells are extensively used in these systems due to their ability to handle high-capacity loads with excellent accuracy.

They are found in floor scales, batching systems, and hopper scales. Beam load cells provide the necessary data for inventory management, quality control, and legal-for-trade transactions to guarantee compliance with industry standards and regulations.

Civil Engineering

Load cells are vital tools for civil engineers in various applications. These devices are employed to measure forces acting upon structures, such as bridges, buildings, and dams. They enable engineers to assess their structural integrity and safety.

In bridge construction, load cells are often installed to monitor the weight distribution and stress levels on different sections of the bridge. They make sure that the bridge can withstand varying loads over time. Similarly, in building construction, load cells are utilized to gauge the loads imposed by occupants, furniture, and environmental factors to aid engineers in designing resilient and durable structures.

By providing real-time data on forces, load cells assist civil engineers in optimizing designs, conducting performance evaluations, and implementing necessary maintenance or reinforcement measures to uphold safety standards and prolong the lifespan of infrastructure.

Automated Manufacturing Processes

Automation is at the heart of modern manufacturing, and beam load cells are pivotal in these systems. They are integral to robotic assembly lines, packaging machinery, and material handling systems. These systems require consistent and precise weight measurements to maintain the efficiency and quality of production. By integrating beam load cells into these processes, manufacturers can ensure continuous monitoring and feedback to better maintain the accuracy of automated systems.

Aerospace and Defense Industry

The importance of beam load cells is significant in the aerospace and defense sectors. These industries require incredibly high standards of precision and reliability. Hence, beam load cells are used to test and monitor everything from the weight of small components to the balance of large aerospace structures. They are also utilized in the development stages of spacecraft and aircraft, where accurate force measurement is critical to ensure safety and functionality.

Advantages of Using Beam Load Cells

Beam load cells are essential components in weight measurement and monitoring. They are commonly utilized in various industries, including manufacturing, logistics, and retail. These devices offer several significant advantages for professionals seeking reliable and efficient weighing solutions.

High Precision and Accuracy

One of the most compelling advantages of beam load cells is their high precision and accuracy. These devices are designed to deliver exact weight measurements for applications where even the slightest discrepancy can lead to significant errors. The strain gauges used in the engineering of beam load cells are highly sensitive and capable of detecting minute changes in weight.

The accuracy of beam load cells is also enhanced by their ability to compensate for factors that could skew measurements, such as temperature fluctuations and external vibrations. Advanced models have temperature compensation features that adjust the output to ensure consistent accuracy across various operating conditions. This level of precision ensures compliance with stringent regulatory standards and helps maintain quality control across various processes.

Robust Construction for Durability

Beam load cells are renowned for their robust construction. Their build ensures long-term durability and performance under challenging conditions. Load cells are typically made from high-quality materials such as stainless steel or aluminum.

These load cells can withstand harsh environments, including high humidity, dust, and corrosive substances. Additionally, the structural integrity of beam load cells makes them suitable for outdoor applications.l They work well in environments such as in construction and agricultural sectors, where they may be exposed to extreme weather conditions.

The durability of beam load cells not only extends the lifespan of the equipment but also reduces the need for frequent replacements. Thereby, providing a cost-effective solution for businesses. Their ability to endure continuous use without degradation in performance is a vital factor for industries that operate around the clock and cannot afford downtime.

Easy Installation and Maintenance

Another significant benefit of beam load cells is their ease of installation and maintenance. These devices are designed with simplicity in mind for easy integration into existing systems without the need for extensive modifications. Many beam load cells come in standard sizes and with mounting hardware for quick and straightforward installation.

Beam load cells can be mounted directly to frames or surfaces where a flat, rigid, and sufficiently thick base is available that will not deform under stress. In most situations, beam load cells are set inside a mounting assembly to provide a suitable mounting surface. They also assist in mitigating rotation, thermal expansion, vibration, and other factors that can affect load cell performance. Load cell mounting also greatly reduces errors caused by off-axis loading.

In terms of maintenance, beam load cells require minimal upkeep. They are generally sealed and self-contained, protecting the critical components from dirt and moisture. Regular calibration and occasional cleaning are typically sufficient to keep them functioning optimally.

Future Trends in Beam Load Cell Technology

Several future trends are poised to redefine the industry standards of beam load cell technology and enhance the capabilities of weighing systems. The integration of beam load cells with the Internet of Things (IoT), advancements in wireless and portable load cell designs, and breakthroughs in material science are at the forefront of these transformative developments.

Integration with IoT for Real-time Data Monitoring

The incorporation of IoT technology into beam load cell systems represents a significant trend that aims to take advantage of real-time data monitoring to optimize operational efficiency and accuracy. Connecting load cells to IoT platforms allows data to be continuously transmitted and analyzed for immediate feedback and actionable insights. This connectivity ensures that deviations are quickly detected and addressed. As a result, this improves quality control and process oversight in industries such as manufacturing and logistics.

Development of Wireless and Portable Load Cells

The shift towards wireless and portable load cell technology marks a critical advancement in the field. These developments are driven by the demand for more flexible and less cumbersome weighing systems. Wireless load cells eliminate the need for physical connections, reducing setup times and enhancing mobility.

Moreover, the portability of these devices allows for easy implementation in various environments, from industrial floors to remote field applications. This flexibility significantly broadens the scope and utility of load cell technologies across different sectors.

Advancements in Material Science for Enhanced Performance

Material science plays a pivotal role in the development of beam load cell technology. Materials innovations contribute to the durability and longevity of load cells and enhance their sensitivity and accuracy. New alloys and composite materials are being explored to withstand harsh environments while maintaining precise measurements. These advancements are critical in industries where extreme conditions may affect the reliability of traditional load cell materials.

Explore the latest in load cell technology and find the perfect solution for your weighing needs at Load Cell Central. Our expert team is ready to assist you with custom electronic weighing systems, interchangeable replacement load cells, and innovative applications personalized to your specific requirements. Visit our website to learn more about our modern solutions and how we can support your business.