Strain Gauges: Key Sensors in Force Measurement and Load Sensing

January 27, 2025

Understanding the diverse applications of strain gauges is crucial for optimizing system performance and enhancing reliability across sectors. By leveraging these sensors, industries can improve product design, operational efficiency, and reduce risks associated with structural failures and inaccurate measurements. Continue reading this blog to learn more about the uses of strain gauges and strain gauge load cells in various applications.

What Are Strain Gauges and How Do They Work?

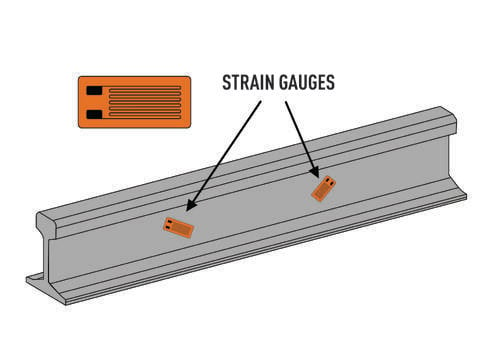

A strain gauge is a device designed to detect and measure the deformation, or strain, of an object when subjected to external forces. It operates on the principle that the electrical resistance of a conductor changes as it undergoes deformation. Typically, a strain gauge consists of a thin metallic foil arranged in a zigzag pattern, mounted on a flexible backing material. This sensor is then affixed to the surface of the object being measured.

As the object experiences stress—whether tension or compression—the strain gauge deforms accordingly, causing its electrical resistance to change. This resistance variation is directly proportional to the strain, providing an accurate measure of the material's deformation.

The strain gauge is connected to an electrical circuit, commonly in a Wheatstone bridge configuration, which enables precise detection of small resistance changes caused by strain. When no load is applied, the bridge circuit remains balanced. However, any deformation caused by external stress results in an imbalance, producing a measurable voltage output that can be recorded.

Strain gauge load cells, which use this principle, are widely used in weighing systems and industrial scales. These load cells measure weight by detecting the deformation caused by the applied load, and the resulting electrical signal is processed and displayed as force or weight, making strain gauge load cells critical for a variety of engineering and industrial applications.

Strain Gauge Applications Across Industries

Manufacturing Industry

Strain gauges are integral in the manufacturing sector, particularly in force measurement for machinery calibration, quality control, and testing. They are commonly used in load cells, which are essential components in presses and CNC machines. By measuring the deformation of a load cell under mechanical force, strain gauges provide precise data on the force exerted during operations.

This information is crucial for calibrating machinery to ensure optimal performance and accuracy. For example, in hydraulic presses, strain gauges help monitor the load applied, preventing overloading and potential damage to the equipment. This helps enhance both safety and reliability in manufacturing processes.

In addition to force measurement, strain gauges play an important role in material testing and structural health monitoring. They are used to assess the strength and durability of materials during manufacturing processes. Strain gauges can be attached to metal or composite materials during stress testing to measure strain under various loading conditions.

In civil engineering, strain gauges are often used on bridges and buildings to monitor structural integrity over time, providing valuable data that can help predict potential failures or maintenance needs. This dual functionality underscores the importance of strain gauges in quality assurance and safety monitoring within the manufacturing sector.

Strain Gauge Applications in the Aerospace Industry

In aerospace, strain gauges are strategically placed on key components, such as wings and fuselages, to measure strain during flight. These sensors detect minute changes in electrical resistance caused by deformation, providing real-time data on the structural integrity of these components.

Continuous monitoring is critical for safety, allowing engineers to identify issues like material fatigue or stress accumulation before they escalate into catastrophic failures. Real-time data enhances decision-making regarding maintenance and operational safety, ensuring the protection of both aircraft and passengers.

Strain gauges are also vital in flight testing, where they simulate various conditions that aircraft may encounter, such as extreme maneuvers or environmental stresses.

Automotive and Heavy Equipment

In the automotive industry, strain gauges embedded in load cells are important for a variety of testing processes. They measure vehicle weight, ensuring compliance with safety regulations and performance standards. During suspension testing, strain gauges assess how components respond to dynamic loads, providing data on stress distribution and potential failure points.

In car crash tests, strain gauges monitor forces experienced by the vehicle structure, allowing engineers to analyze the effectiveness of safety features like crumple zones and airbags.

Strain gauges are also used in heavy machinery to monitor operational stress levels. In cranes, forklifts, and other industrial machines, strain gauges measure the strain on key components, providing real-time data to prevent overloads and mechanical failures.

Civil Engineering

In civil engineering, strain gauges are employed to assess the structural integrity of infrastructure by measuring deformation under various loads. By attaching strain gauges to key structural components, engineers can monitor strain on bridges and dams over time, detecting early signs of potential failure.

Strain gauges are also used in earthquake and load testing to evaluate how structures respond to seismic forces and heavy traffic. By measuring strain during these events, engineers can predict stress levels in buildings and roads, helping design resilient infrastructure capable of withstanding dynamic forces.

For example, strain gauges provide real-time data on how much a building deforms during an earthquake, enabling engineers to assess its safety immediately after the event.

Medical Field

In the medical field, strain gauges are integrated into robotic surgical systems, helping surgeons apply the correct force during delicate procedures, which enhances patient safety and improves surgical outcomes. They are also used in devices like kidney dialysis machines and syringe pumps to monitor fluid flow rates, ensuring accurate medication delivery.

Strain gauges play a role in patient lift systems and weighing scales, helping to monitor patient data and improve care. In wearable medical devices, strain gauges are increasingly used to monitor muscle force and joint load. These sensors can be embedded in devices designed for orthopedic rehabilitation, allowing real-time assessment of joint stress during physical activities.

Advancements in flexible and hydrogel-based strain sensors have expanded their applications in wearable technology, improving comfort and effectiveness for continuous health monitoring. This integration helps better understand biomechanics and allows for more personalized rehabilitation programs.

How Strain Gauges Drive Innovation Across Industries

Strain gauges are versatile sensors with broad applications in industries such as civil engineering, aerospace, automotive, and healthcare. Strain gauge load cells, in particular, are crucial in precision force measurement systems, converting mechanical loads into accurate electrical signals.

To explore innovative solutions for strain measurement and load cell applications, visit Load Cell Central. Our load cell gauging services can help enhance the reliability and effectiveness of your projects.